The Hidden Cost of Designs That Can't Be Built

You've seen the CAD model. It's elegant, functional, and meets every performance requirement. The team is excited to move forward. Then you send it to manufacturing.

What comes back isn't enthusiasm—it's a list of problems. The tolerances are too tight for standard equipment. The geometry requires custom fixturing. Assembly will need specialized tooling. Suddenly, your timeline extends by months, your budget balloons by 40%, and you're facing fundamental redesigns that could have been avoided.

This scenario plays out in product development more often than it should. A product that's difficult to manufacture doesn't just cost more—it takes longer to launch, often compromises quality, and can turn a promising product into a struggle from day one. That's why Design for Manufacturability isn't an optional step or a final checklist item. It's the foundation of successful product design.

What "Design for Manufacturability" Really Means

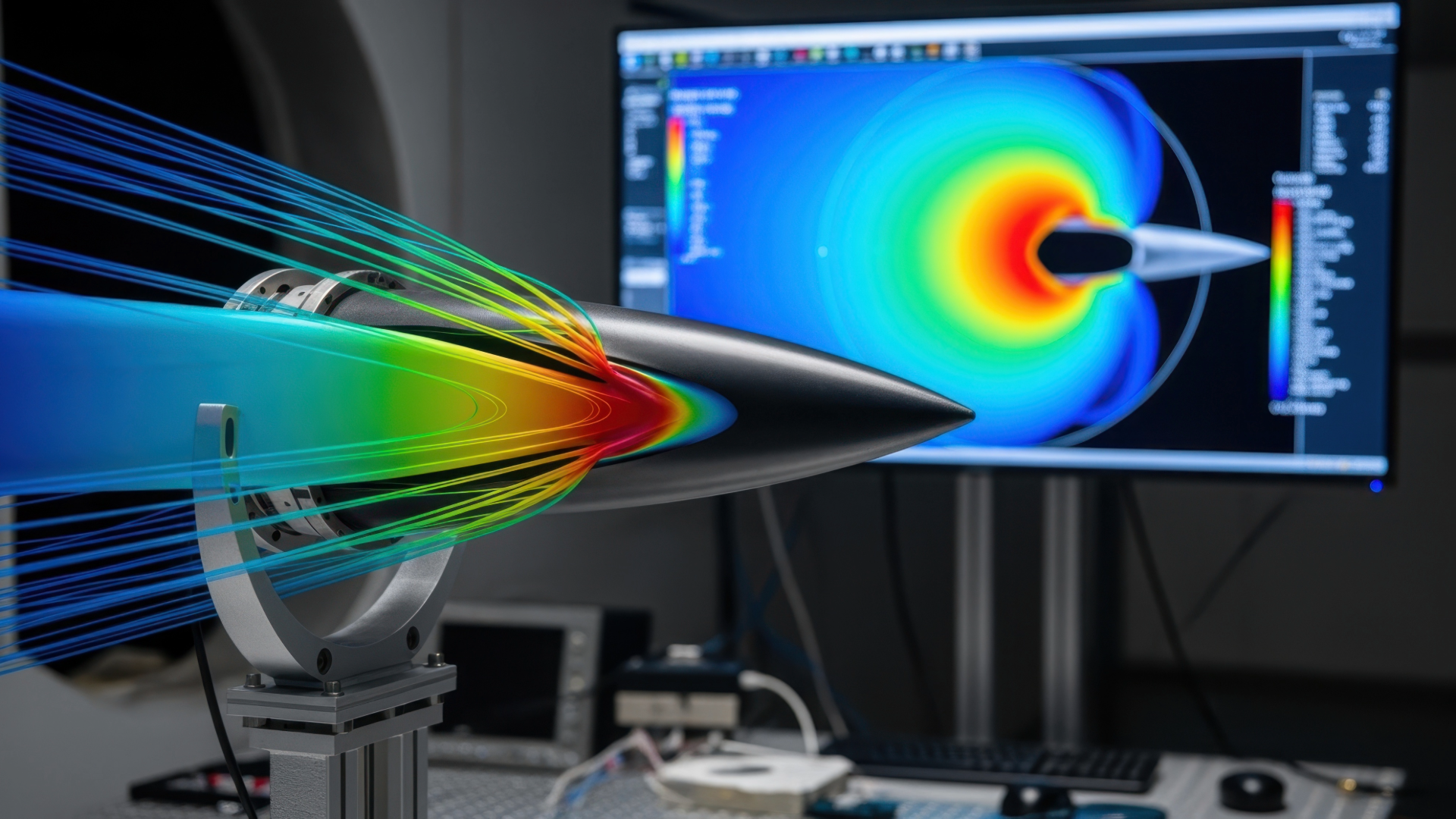

Design for Manufacturability (DFM) is the practice of optimizing a product design so it can be built easily, repeatably, and cost-effectively using existing manufacturing processes. The goal isn't to water down your design vision—it's to eliminate unnecessary complexity before the first prototype is made.

DFM applies at every stage of development, from initial concept through detailed design. It's a mindset that asks a simple question at each decision point: "How will this actually be made?"

The core principles include:

Simplifying part geometry to reduce machining time and tooling complexity

Standardizing features and materials to leverage proven processes and reduce supply chain variability

Designing to minimize setup and tooling changes that add time and cost to every production run

Aligning tolerances with realistic manufacturing capabilities rather than specifying precision that doesn't add functional value

When these principles are applied consistently, they transform how a product moves from concept to market.

The Business Case for DFM

For engineering managers, product leads, and founders, DFM translates directly into competitive advantage. Here's how engineering decisions impact business outcomes:

| Engineering Benefit | Business Impact |

|---|---|

| Fewer design changes late in the process | Shorter development timelines |

| Simplified parts and assemblies | Lower production cost |

| Process-aligned tolerances | Higher yield, fewer defects |

| Optimized material selection | Reduced waste and supplier issues |

| Early manufacturer input | Faster transition from design to production |

The pattern is clear: the earlier manufacturability is considered, the greater the return on every design dollar. Companies that integrate DFM from the start consistently outpace competitors who treat it as an afterthought.

How DFM Reduces Risk and Cost

Every design decision—from part geometry to tolerance specifications—creates downstream implications for manufacturing. DFM ensures those decisions work in your favor.

Tooling Efficiency: Parts designed with manufacturing in mind can be machined or molded without complex fixturing, reducing both setup time and the risk of errors. A design that requires three setups instead of five doesn't just save time—it eliminates opportunities for dimensional drift and quality issues.

Material Optimization: The right material balances performance requirements with manufacturability. A slightly different alloy or grade might machine more cleanly, reducing tool wear and improving surface finish. The result is faster production and more consistent parts.

Tolerancing for Reality: One of the most common—and expensive—mistakes is specifying overly tight tolerances where they don't add value. A dimension held to ±0.001" when ±0.005" would serve the function equally well can double or triple machining costs. DFM means understanding where precision matters and where standard capabilities are sufficient.

Process Compatibility: Different manufacturing processes—casting, sheet metal forming, CNC machining, additive manufacturing—each have inherent capabilities and constraints. Designing a cast part with features that would be simple to machine but problematic to cast creates unnecessary problems. DFM aligns design decisions with the intended process from the start.

The takeaway: every decision made in design has downstream cost implications. DFM ensures those decisions work for you, not against you.

When to Apply DFM in the Product Lifecycle

Timing matters enormously. A manufacturability issue caught during concept development might require an hour of redesign work. The same issue discovered during pilot production can require new tooling, revised fixtures, and weeks of delay.

Here's the optimal approach:

Concept Phase: Evaluate which manufacturing processes align with the product's performance goals, volume requirements, and budget constraints. Making this decision early sets realistic boundaries for the design.

Pre-Prototype Phase: Apply formal DFM reviews to eliminate manufacturability risks before committing to detailed design. This is when geometry can be simplified, features can be standardized, and materials can be optimized with minimal rework.

Before Production: Validate manufacturability through supplier review or internal process analysis. Even with good DFM practices earlier, production-scale considerations can surface issues that need addressing.

The cost to fix manufacturability issues rises exponentially as the design matures—early attention pays off many times over.

Common DFM Pitfalls (and How to Avoid Them)

Even experienced teams fall into predictable traps:

Designing parts without clear process assumptions. When the manufacturing method isn't decided until after the design is "complete," you're designing in the dark. The part might need fundamental changes to suit the actual process.

Over-constraining tolerances "just to be safe." Tighter tolerances don't automatically mean better parts—they mean more expensive parts. Specify precision where it matters; accept standard capabilities elsewhere.

Ignoring assembly access or fastening methods. A beautifully designed component that can't be assembled efficiently creates production bottlenecks and quality risks. DFM considers the full assembly sequence, not just individual parts.

Selecting materials based solely on performance data, not process compatibility. A material might have ideal properties on paper but be difficult to source, hard to machine, or prone to distortion. The "perfect" material that creates manufacturing headaches isn't perfect.

DFM isn't about compromise—it's about alignment between design intent and manufacturing reality. The best designs achieve their functional goals through manufacturable means.

The JTJ Design Approach to DFM

At JTJ Design, we integrate manufacturability into every design decision. Our approach combines deep engineering understanding with process awareness—ensuring designs are optimized for how they'll actually be built, not just how they look on screen.

We provide:

Early manufacturability reviews that identify potential issues when changes are still straightforward and inexpensive

Design simplification and cost analysis to help you understand the true cost drivers and where optimization delivers the most value

Vendor collaboration and production handoff support to ensure smooth transitions from development to manufacturing

Our clients avoid the costly redesign cycles, delayed launches, and production problems that plague projects where manufacturability is treated as someone else's problem.

Design Smart, Build Better

Design for Manufacturability isn't an extra step—it's a safeguard for your investment. Every design decision that ignores manufacturability adds risk, time, and cost. Every decision made with DFM in mind accelerates success.

The products that reach market quickly, stay within budget, and deliver consistent quality aren't lucky—they're the result of disciplined DFM from the start.

If you're developing a product that needs to move seamlessly from design to production, let's talk. JTJ Design can help ensure your next design is ready for manufacture—efficiently, reliably, and on schedule.

SHARE