Simulation & Analysis Services

Bring Confidence to Your Designs with Simulation-Led Engineering

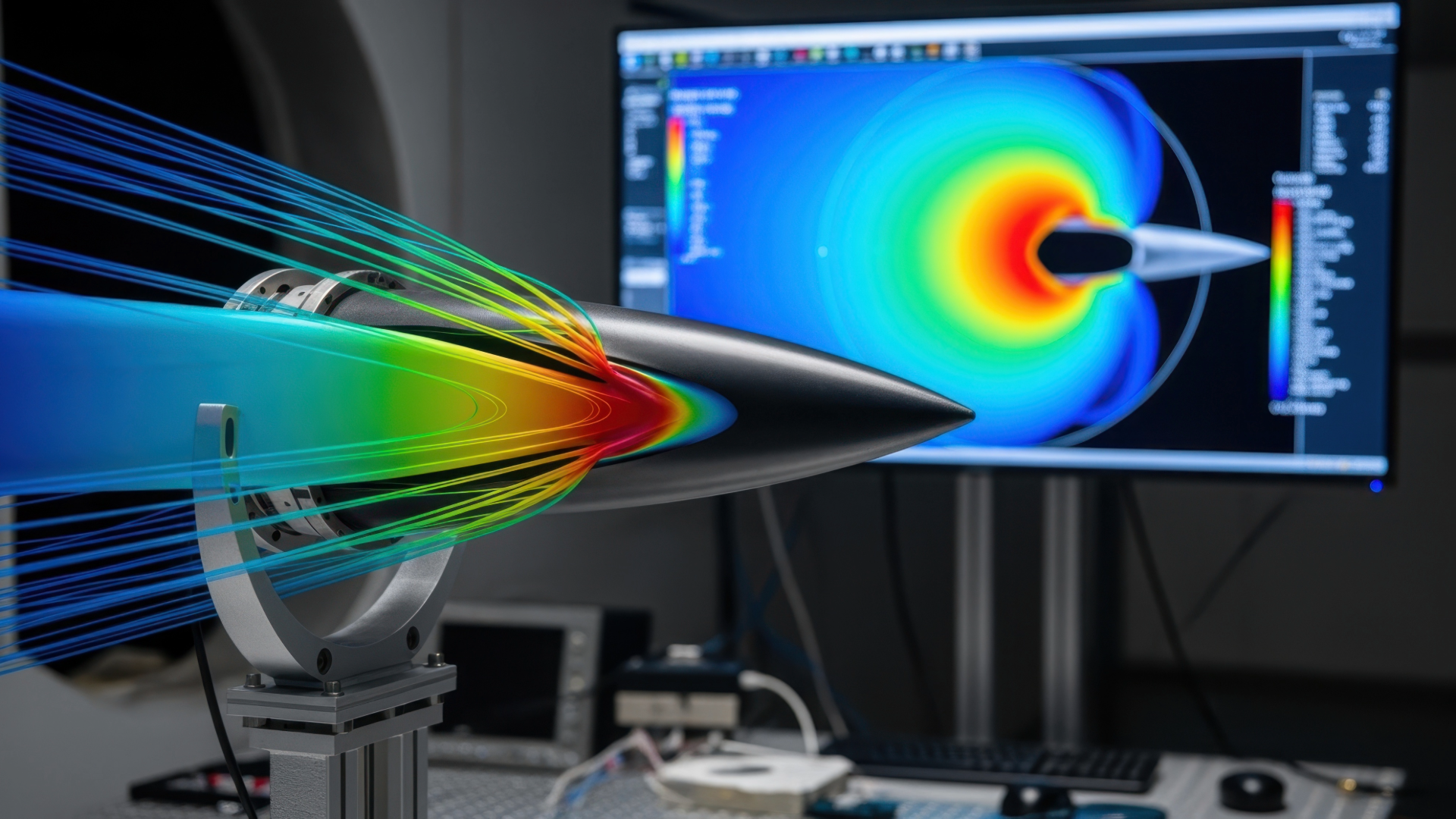

From validating concepts to optimizing production-ready designs, our physics-based simulations—FEA, CFD, and multiphysics—transform complexity into clarity, reducing risk and accelerating your development timeline.

Engineering insight, validated by physics

What Are Simulation & Analysis Services?

Using advanced simulation tools, we predict how your designs behave under real-world conditions—before a prototype exists. Whether it's structural loads, thermal effects, fluid dynamics, or coupled physics, our simulations validate and enhance design performance early in the development cycle.

Comprehensive Simulation Capabilities

Simulation and Analysis Capabilities

Using tools like SolidWorks Simulation, SolidWorks Flow, Abaqus, and NASTRAN, we provide a full spectrum of simulation services, tailored to your project’s needs:

Structural & Dynamic FEA

Predict performance under real-world loads.

We evaluate stresses, deformations, fatigue life, and vibrations to ensure your designs hold up under static, dynamic, or impact conditions.

Example: Prevent premature fatigue failure in brackets, frames, or rotating machinery.

CFD & Thermal Simulation

Understand how fluids and heat affect your product.

We analyze flow distribution, turbulence, pressure drop, and heat transfer to guide cooling strategies and improve efficiency.

Example: Optimize airflow through enclosures to eliminate overheating in electronics.

Multiphysics & Coupled Simulations

Tackle complex, real-world interactions.

We solve problems where physics overlap—such as fluid-structure interaction, thermo-mechanical coupling, or electro-thermal loading.

Example: Predict thermal stress in electronics subject to airflow cooling.

Optimization & Design Exploration

Go beyond “safe”—find the best design.

With topology optimization, DOE, and parameter sweeps, we help you minimize weight, reduce cost, and maximize performance.

Example: Reduce component weight by 25% while maintaining fatigue strength.

Validation & Test Correlation

Align virtual and physical results.

We refine models using lab data, quantify uncertainty, and build confidence in simulation-driven decisions.

Example: Match FEA vibration predictions with shaker-table test results.

Automated Workflows

Scale your simulations with efficiency.

Custom scripting, batch studies, and CAD/PLM integration ensure repeatable processes that reduce manual effort and errors.

Example: Automate bolt-preload simulations across 100 design variants.

Why Our Clients Choose Us

Benefits of Simulation & Analysis

We apply a simulation-driven design approach to ensure designs are validated before they ever reach the shop floor.

When it comes to simulation and analysis, our clients value more than just technical results—they rely on us for clarity, confidence, and practical guidance. We bridge the gap between complex physics and real-world engineering decisions, delivering insights that are accurate, actionable, and aligned with manufacturing realities. By integrating seamlessly with design and development teams, we help organizations accelerate timelines, avoid costly rework, and make informed choices that balance performance, cost, and risk.

What you can expect:

- Faster, Smarter Development – Validate early to catch issues before manufacturing—reducing rework and time-to-market.

- Optimized, Cost-Efficient Designs – Evaluate material, cost, weight, and performance trade-offs virtually—making informed decisions early.

- Built for Real-World Execution – Our recommendations are grounded in manufacturing realities, ensuring practical and actionable solutions.

Our Proven Approach

A Clear, Structured Path to Better Designs

From discovery through delivery, our simulation process ensures accuracy, efficiency, and actionable results..

Successful simulation isn’t just about running software—it’s about following a disciplined approach that translates engineering questions into reliable answers. Our process guides every project through well-defined stages: capturing requirements, building accurate models, iterating and validating, and delivering insights that drive better design decisions. The result is a streamlined workflow that reduces uncertainty and maximizes confidence in your product’s performance.

1. Discovery & Scoping

We start by understanding your product goals, functional requirements, and performance targets. This includes reviewing CAD models, expected load conditions, operating environments, and acceptance criteria. By defining the problem space up front, we ensure that every simulation is purposeful and aligned with your business objectives.

2. Setup & Baseline Analysis

Next, we prepare geometry, create an appropriate meshing strategy, select materials, and define boundary conditions. Baseline simulations are then run to establish reference performance. This stage builds the foundation for accuracy and efficiency in subsequent studies.

3. Iterate, Validate & Refine

Using design of experiments, parametric sweeps, and optimization tools, we evaluate design alternatives and identify improvements. Where available, results are correlated with test data to validate model fidelity. This iterative process uncovers insights that reduce risk, improve performance, and balance cost with manufacturability.

4. Deliver & Support

Finally, we provide a complete set of deliverables—simulation models, annotated plots, animations, and detailed reports. Recommendations are presented in plain language for both engineers and decision-makers. We also offer optional workshops or training to transfer knowledge, ensuring your team can confidently build on the results.

Industries We Serve

Simulation Expertise Across Sectors

Tailored analysis for industries where performance, safety, and reliability matter most.

Every industry faces unique engineering challenges—whether it’s reducing weight in aerospace, managing heat in medical devices, or preventing cavitation in pumps. Our simulation and analysis services are adaptable across sectors, giving your team accurate predictions and actionable insights no matter the application. By combining deep technical expertise with an understanding of industry-specific demands, we deliver solutions that help our clients bring safer, more efficient, and more competitive products to market.

Answers to Your Top Questions

Frequently Asked Questions

Have questions about our simulation and analysis services? Here’s everything you need to know to get started with confidence.

How long does a simulation engagement take?

Timeline varies by scope; small scoped validation runs can be done in days, full optimization programs may take several weeks. We provide a tailored schedule after discovery.

Can you work with my CAD files?

Yes — we accept native SolidWorks CAD and neutral formats like IGES and STEP.

Do you offer model validation with physical testing?

Yes. We design test correlation plans and help interpret experimental data to improve model fidelity.

What industries do you specialize in?

We have deep experience across aerospace and defense, marine systems, and rugged electronics enclosures. If your application is unique, we’ll scope a fit-for-purpose plan.

Ready to Reduce Risk and Speed Development?

Let’s schedule a scoping call to review constraints, timelines, and define what simulation success looks like for your project.